Oct 11 , 2023

Additives are usually added into polymers to modify and improve certain characteristics, such as stiffness, strength, color, weatherability, flammability, arc resistance for electrical applications, and ease of subsequent processing. These additives are described below:

1. Fillers

Fillers are particles added to plastics to...read more

Nov 14 , 2022

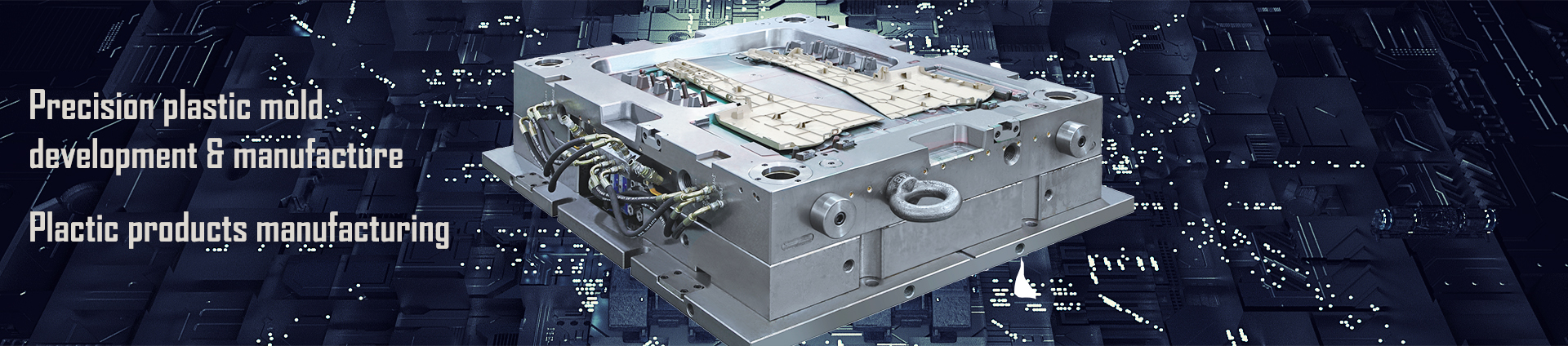

Basic Injection Mold Types

The most common injection mold types which used in E-Mold: two-plate mold; three-plate mold; hot-runner mold.

1. Two-Plate Mold

A two-plate mold consists of two plates with the cavity and cores mounted in either plate. The plates are fastened to the press platens. The moving half of the...read more

Feb 29 , 2020

Below specification defines E-mold acceptance criteria of cosmetic inspection.

Classification on product surfaces.

Class 1 Surface: Visible "ofter" by user.

Class 2 Surface: Visible occasionlly or likely to be seen by user.

Class 3 Surface: Normally not visible or only visible during installation.

1. Acceptance...read more

Feb 28 , 2020

Injection molding is principally used for the production of thermoplastic parts, although some progress has been made in developing a method for injection molding some thermosetting materials.

The problem of injecting a melted plastic into a mold cavity from a reservoir of melted material has been extremely difficult to solve for thermosetting plastics...read more

Feb 22 , 2020

The parts of an injection mold are divided into the following categories based on their different functions.

a) Mold closing state b) Mold opening state

1-Moving half of a mold; 2-Fixed half of a mold; 3-Cooling channel; 4-Clamping plate of the fixed half; 5-Locating ring; 6-Sprue bush; 7- Punch; 8-Guide pillar; 9-Guide...read more

May 23 , 2019

The plastic injection molding cycle consists of four phases:

1. Clamping is the closing of the mold.

2. Injection is the filling of the mold.

3. Cooling is the hardening of the plastic within the mold.

4. Ejection is the removal of the plastic part from the mold.

Clamping

During the clamping portion of the injection...read more

Displaying 1 to 6 (of 6 news)